Bin Weighing and Dozing System

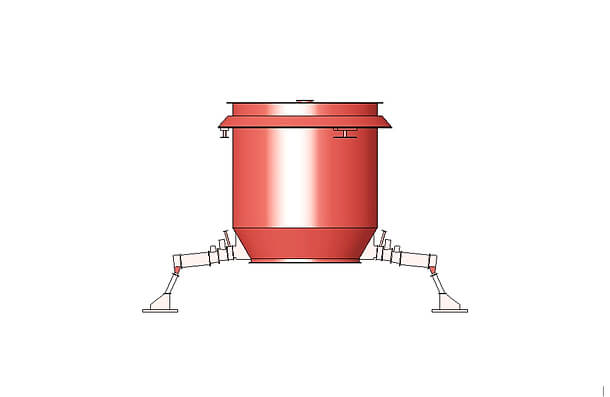

Koenig developed a unique system that allows accurate mass indication of most bins, silos and tanks. The key to the system are Load cells and fluidization & extraction.

Koenig offers wide range of complete Bin Weighing and Dozing system to meet the accuracy requirement up to ±1% on Full Scale. A typical Koenig Bin Weight Indicator system features several load cells connected to a special purpose micro controller. The micro controller provides both analog and digital interfacing options to other systems.

We supply the perfectly matched components like Load cells, Fabricated Bins, Aeration and Extraction system, Metering Flow Control valve and other necessary mechanical components. The weight of the contents of silos, bins, mixers or reactors can be determined with the help of these components.

Applications of Koenig Bin weighing and Dozing systems:

- Kiln / calciner Feed system in Process Industries.

- Truck Loading system for Raw materials and finished products.

- Fly Ash measuring and mixing in grinding system in Cement Industries

- Our standard Bin capacities are 50MT to 400MT having bin diameter 2m to 7m.

- Special sizes and configurations on request.

Need help? Our experts have the right solution for your Bin weighing and dozing challenges. Rest assured, our services are top notch. Feel free to click the button to below and contact us via call, email or by simply filling the form.